Waste to energy plants - Comef

Our waste to energy plants

Our waste to energy plants are an important source of energy for national and international countries.

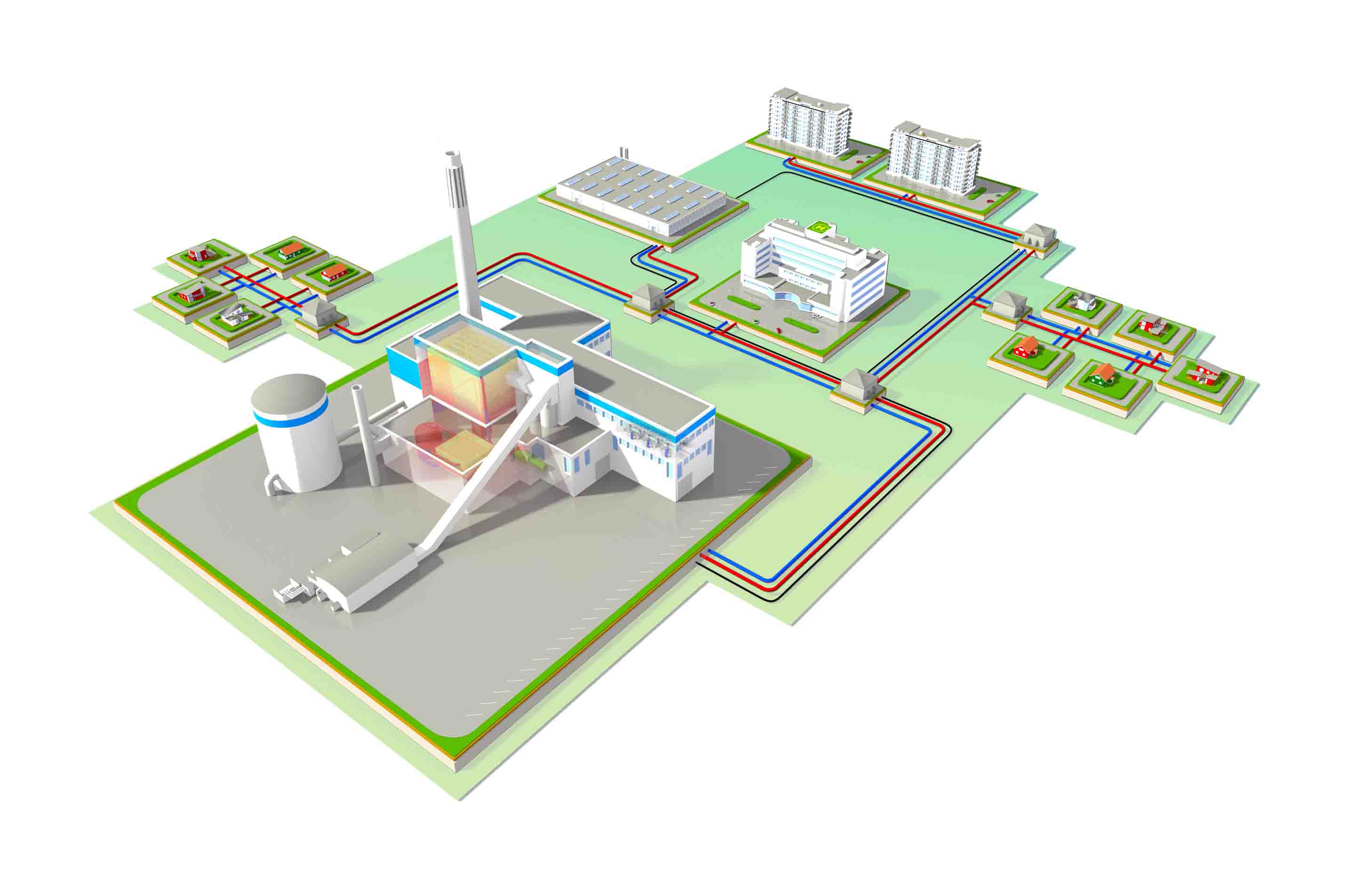

Agricultural waste, horticulture, aquaculture, forestry, preparation and processing of fruit, vegetables, cereals, edible oils, cocoa, coffee, tea, tobacco, the production of canned food, wood processing and its derivatives, of the production and processing of paper and cardboard, packaging is some of the waste that is recovered energetically in our plants to produce electric energy and heat for industrial processes and civil services (district heating and cooling).

Comef plants energetically recover municipal solid waste (MSW) and refuse derived fuel (RDF), solid fuels derived from the mechanical treatment of undifferentiated waste.

- Municipal solid (MSW) waste to energy plants for urban solid waste

- Refuse derived fuel (RDF) waste to energy plants

The waste energy recovery is achieved through high performance systems both in terms of heat recovery and environmental efficiency. The waste to energy plant has environmental advantages because it does not use traditional energy resources (avoiding the emissions of greenhouse gases typical of plants fueled by fossil fuels) or disposal in landfills.

RDF, which stands for “Fuel Derived from Waste”, and the SSF, acronym for “Solid Secondary Fuel”, are obtained from a cycle of refining of undifferentiated waste that includes shredding, drying, stabilization of the organic fraction, separation of metals and export of aggregates; in this way a non-hazardous fuel is obtained with a good energetic content and constant chemical-physical characteristics that comply with specific technical standards.

Generation and cogeneration

District heating systems from cogeneration plants enable greatest global energy efficiency to be achieved; in fact, the power plant is able to produce electric energy and recover at the same time the thermal energy released in the thermodynamic process.

Our waste to energy plant features

At present, waste to energy plants are absolutely safe, both for man and for the environment; just think that the emissions into the atmosphere are also tens of times lower than those of the fossil fuel and cement plants and, for some parameters, they are even lower than the boilers fired by wood and pellets.

Volume and weight reduction

Recovery of waste energy

Total respect for the environment

High performance

Continuous service

Reduced consumption

Easy and quick maintenance

We have implemented national and international projects

Comef, founded in 1968, is now a leading player in different sectors and serving every customer’s needs.