Services - Comef

OUR SERVICES

In an increasingly complex world, where development and energy must combine with the environment and sustainability, we are able to propose solutions that meet these requirements.

Design and Engineering

Comef is able to perform all the basic and detailed engineering for energy plants, technological systems, boilers, exchangers, industrial plants, buildings, machinery and steel structures, waste disposal and recovery plants, tanks and tank containers.

Our staff skills allow to take care of all the authorization procedures related to the projects.

Activities carried out by our technical staff, composed of process engineers, energy engineers, chemists, plumbers, materials, mechanics, structural engineers, civilians, electrical engineers, environmentalists, are among others:

- Thermodynamic design

- Process engineering

- Mechanical design

- Finite element analysis

- Civil and metallic structural design

- Design of thermal and acoustic insulation

- Electrical and electro-instrumental design

- Piping stress analysis

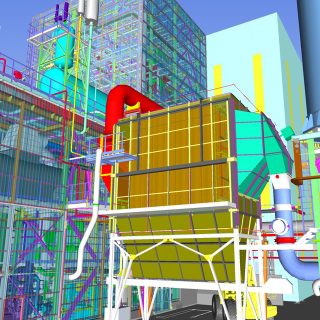

- Plant modeling

- Overall design and detail

Design and engineering are carried out through the most modern software. Drawing are carried out through the most advanced 3D CAD systems.

Existing plant retrofit

Demands for better performance, both in terms of energy efficiency and environmental protection, increasingly see us engaged in engineering evaluations and achievements aimed at this purpose. Our technical staff proceeds to review the processes of existing systems and identifies the implementation interventions of new technologies and functionalities necessary to improve the operating and environmental conditions of the plants.

Existing plant revamping

Our ability and competence, acquired over many years of experience, for the best management of plant revamping interventions. Disassembly of existing systems and design, construction and assembly of new plants, responding to the best available technologies, in the same areas.

Metal working

Production makes use of advanced technology and high automation systems and machineries for every manufacturing process.

The experience gained in over fifty years of history allows us to process a vast range of materials: from carbon steel to alloy steel, from stainless steel to nickel alloys, to titanium alloys.

Deformation and cut

- Watercut

- Lasercut

- Press-bending and rolling

- Pipe bending

- Pipe expanding

- Pipe end forming

- Rastrematura tubi

Machining

- Five axis control numeric milling

Welding

More than 400 welding procedures qualified for different materials and thicknesses.

- Manual process GTAW, SMAW

- Semi-automatized process GMAW, FCAW

- Automatized process SAW, FWP (fin welded panel)

- Robotized process GTAW, GMAW

Metal anti-corrosion coatings

Comef realizes anticorrosive treatments of metal items of industrial plants, petrochemical and chemical plants, power plants, civil engineering works.

Welded overlays and cladding

Anticorrosive surface coatings welded in nickel alloys on parts of boilers or skid waters or fluegas ducts are a pride for our company that has long been equipped with automated systems for overlays and cladding.

Surface preparation and painting

Comef is able to perform protective treatments both on new and existing parts, both at its own production site and at the Customer’s sites.

Surface preparation is done by sandblasting and shot blasting; coating surfaces using paint products.

Erection and Maintenance

Comef is able to provide complete services to the customer in terms of assembly: mechanical, electrical, instrumental, thermal insulation, sound insulation, together with civil works, plant commissioning and related training of user personnel are relevant Comef can offer to the Customer.

Comef also provides the Customer with all kinds of maintenance activities, including in-plant maintenance with fixed staff presence, maintenance with call or maintenance upon contract.

We have implemented national and international projects

Comef, founded in 1968, is now a leading player in different sectors and serving every customer’s needs.